Specifications / Content

-

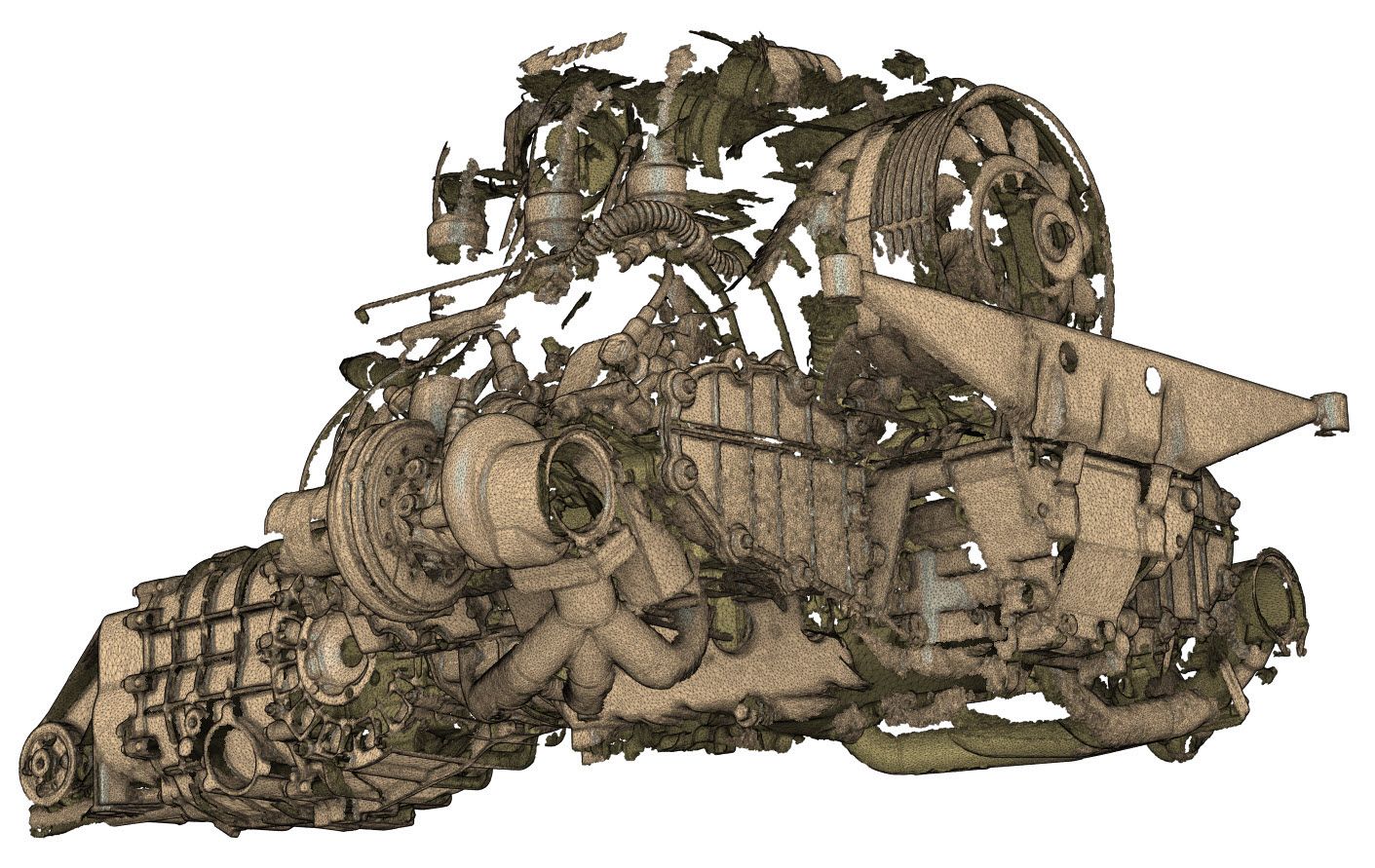

3.6L (donor engine was from my 1990 Carrera 964)

-

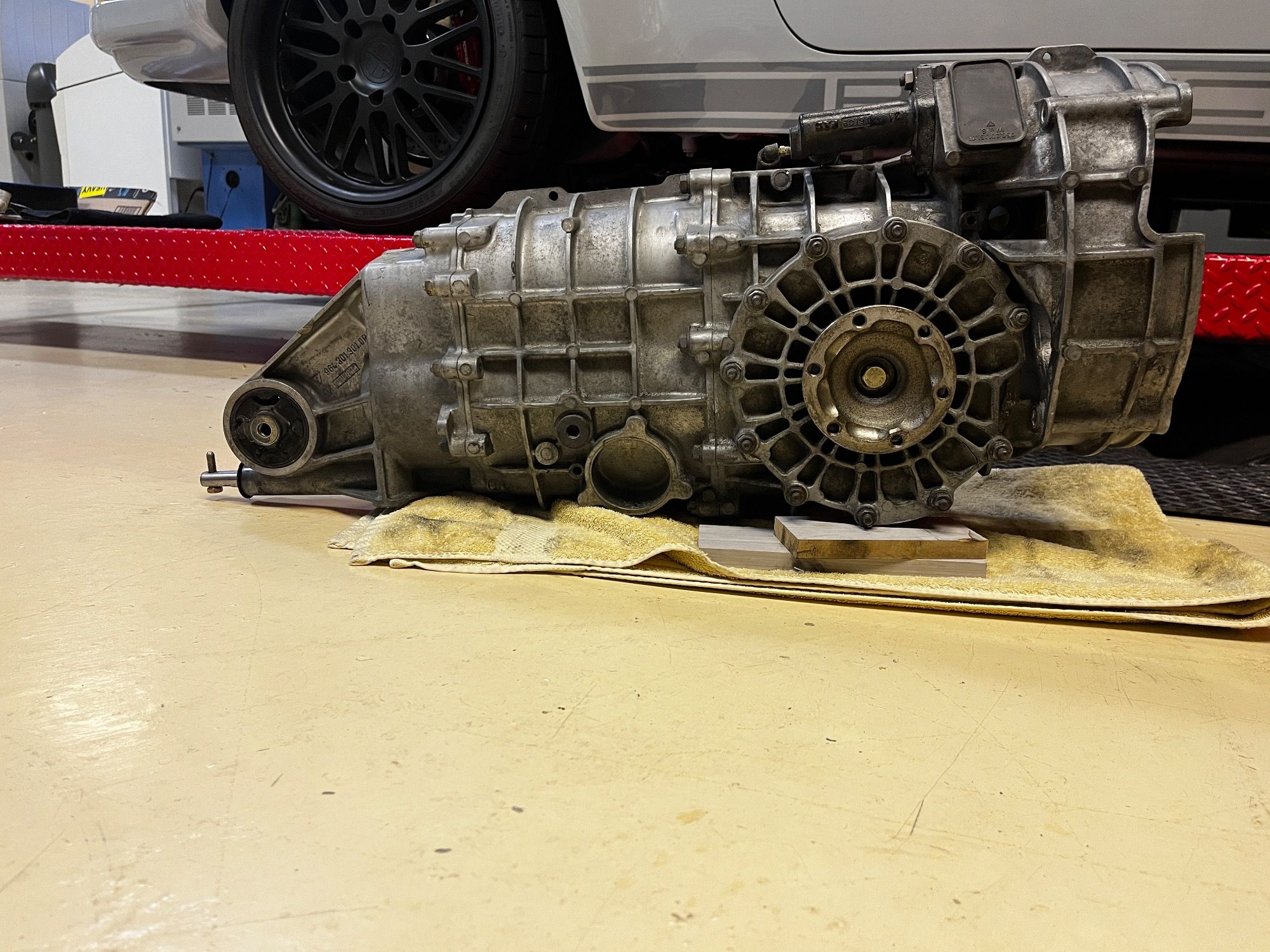

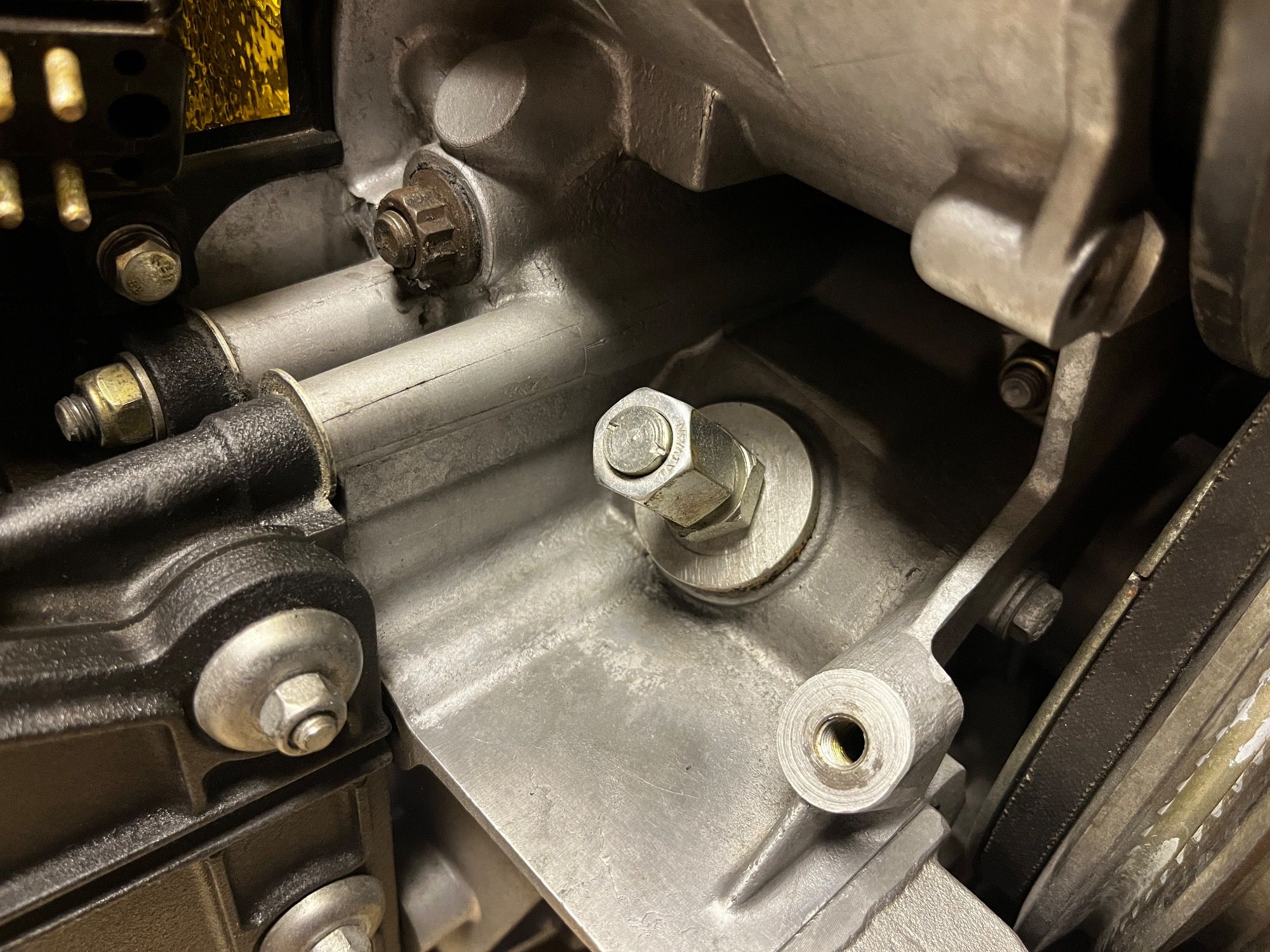

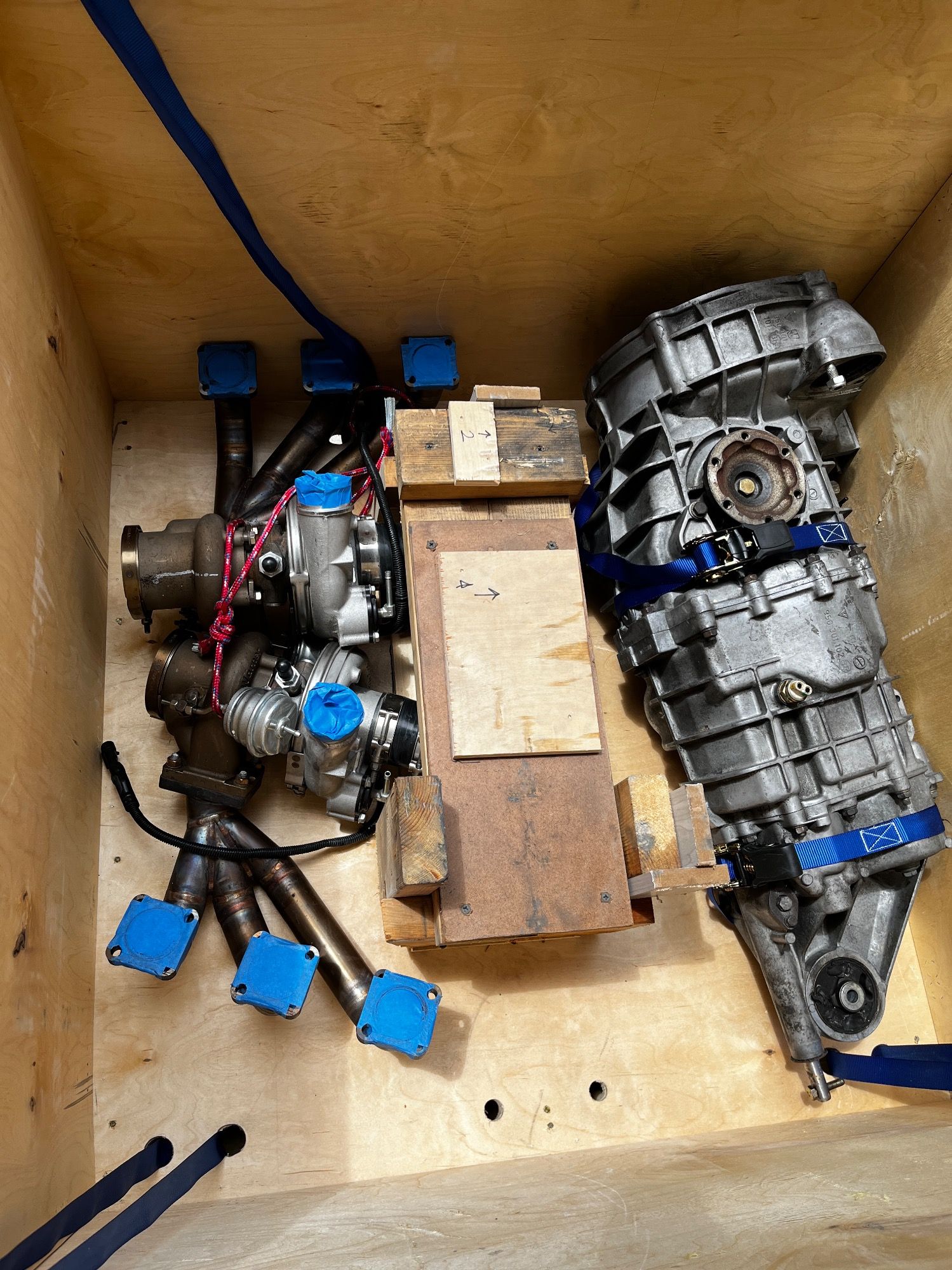

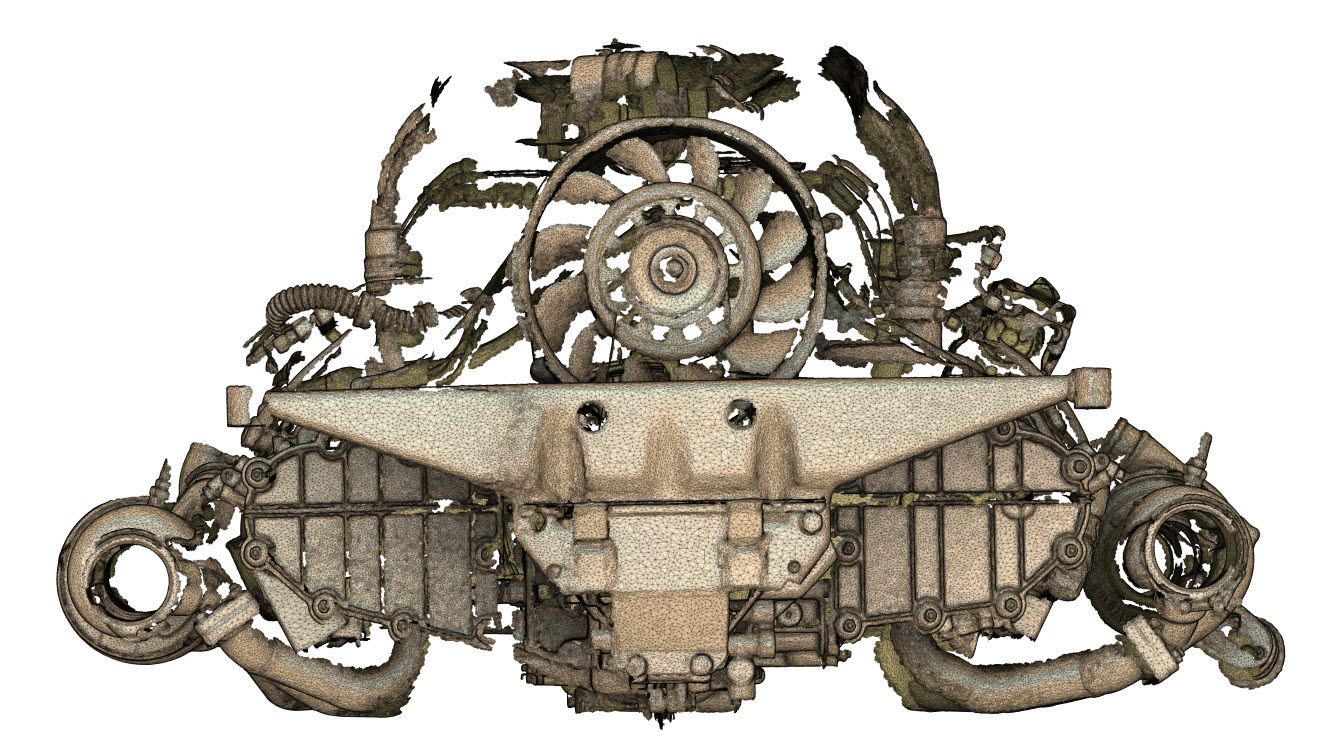

Includes G50/03 transmission (from 90-94 Carrera 2) with Quaife limited slip differential

-

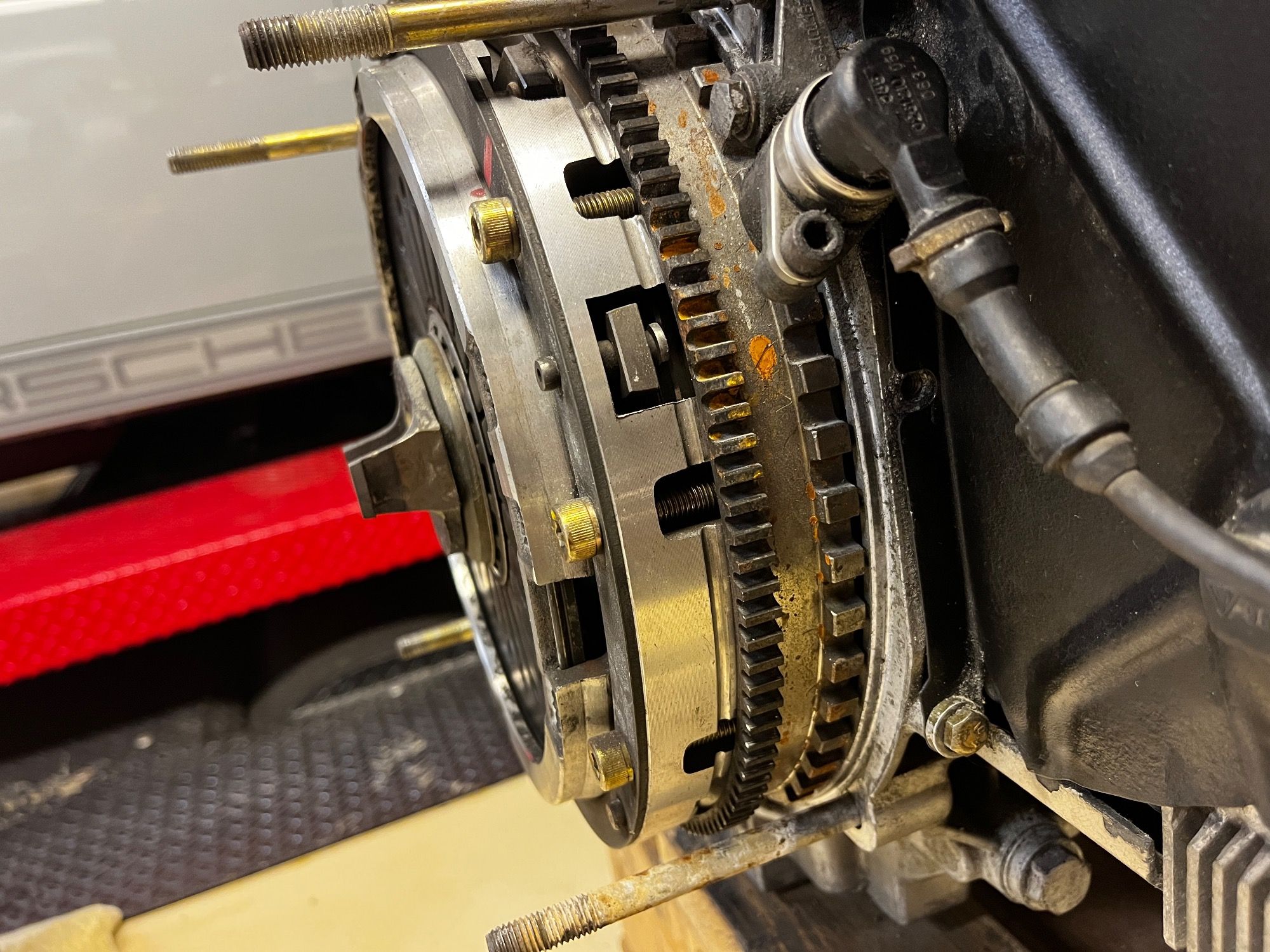

996TT clutch (very streetable yet torque-capable)

-

Engine rebuilt in 2007

-

Less than 1000 miles since rebuild

-

Compression lowered using P’s and C’s from a factory turbo engine (8:1 compression)

-

Cylinder heads rebuilt by Protomotive, machined to match cylinders

-

Upgraded camshafts (John Dougherty Racing Cams “Super C2” grind)

-

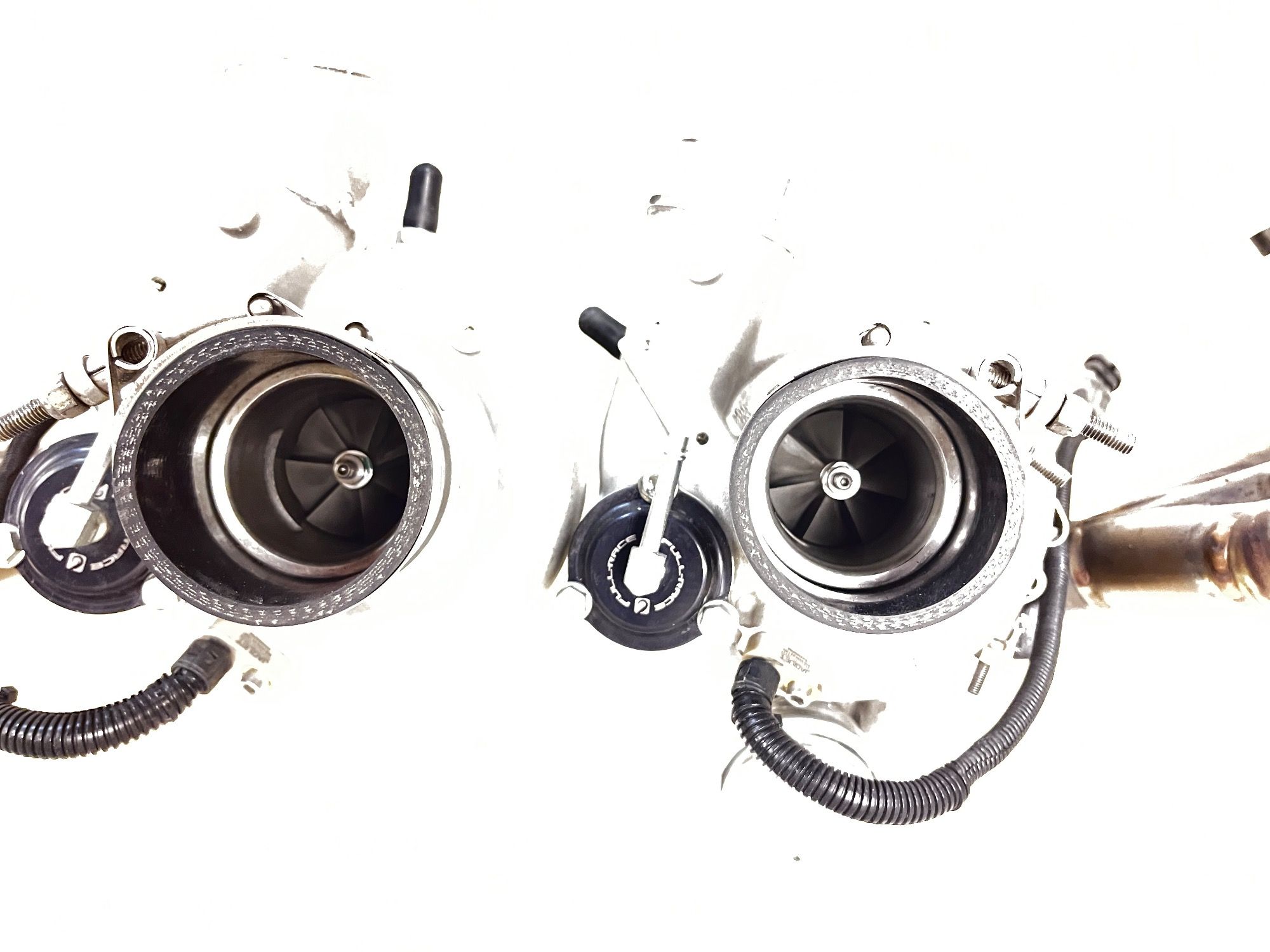

Twin BorgWarner EFR 6258 turbochargers

-

Full-Race custom exhaust manifolds (no heat boxes)

-

Boost charge pipes (aluminum) and exhaust pipes (stainless)

-

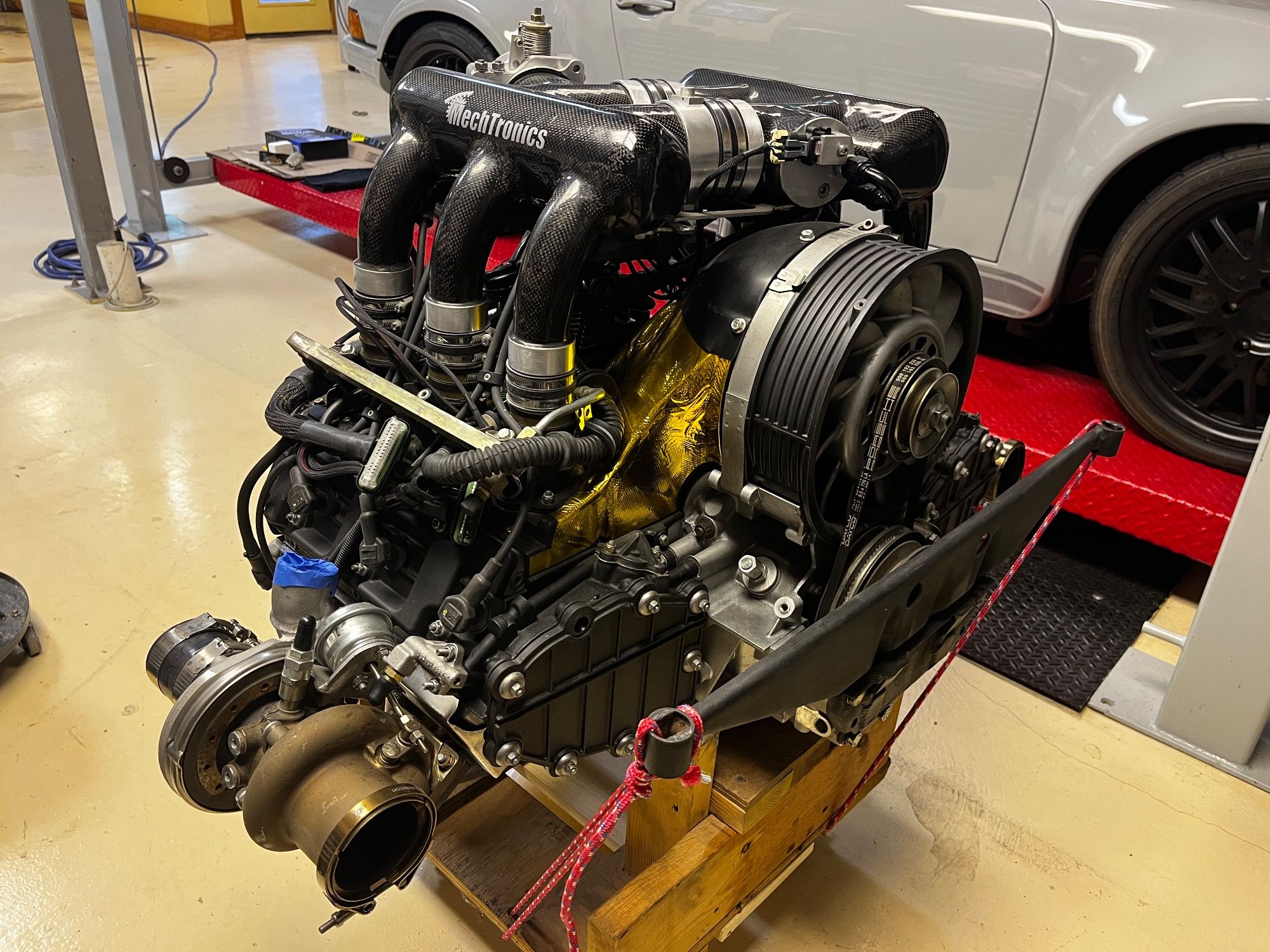

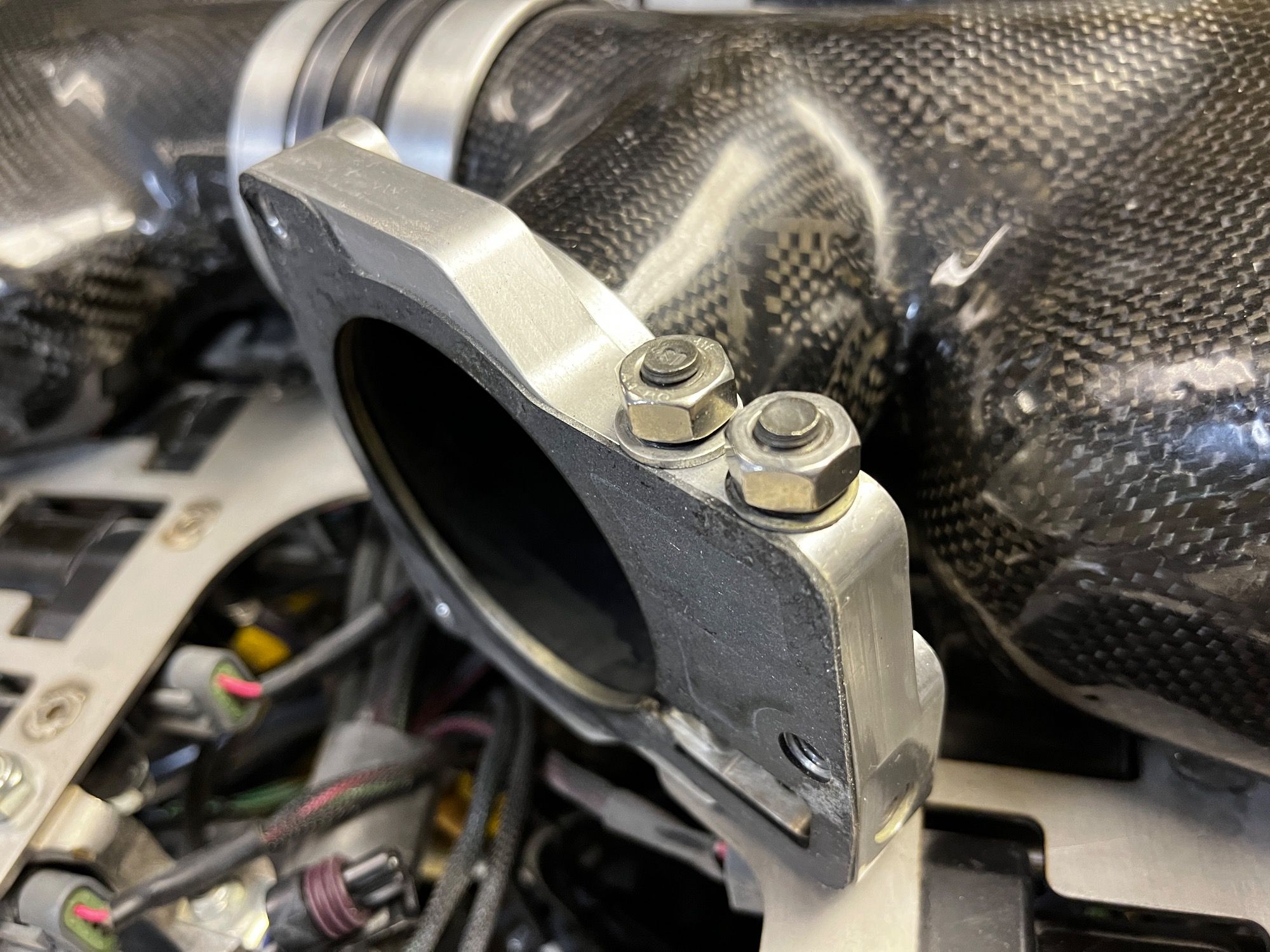

Custom carbon fiber intake manifold

-

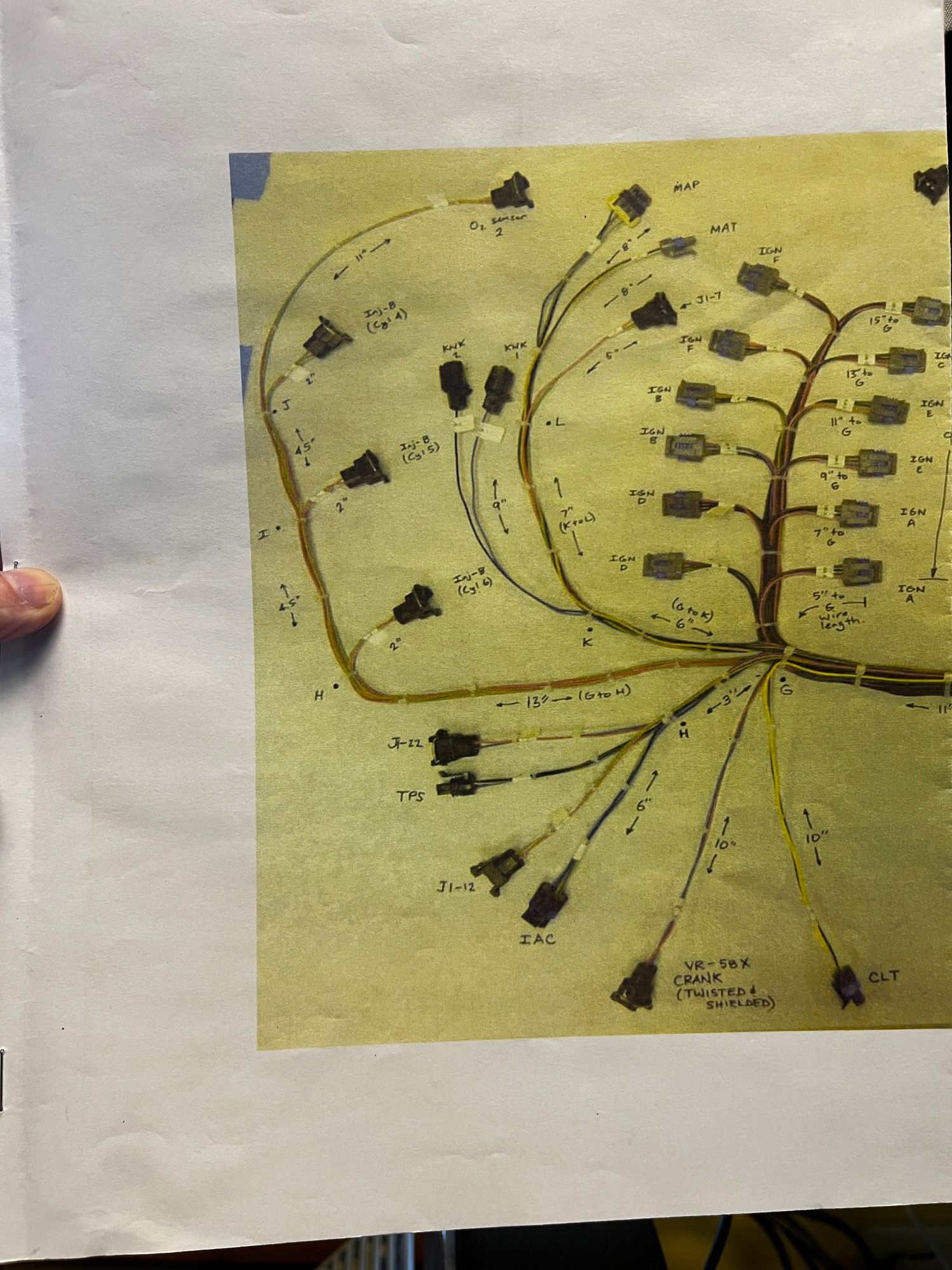

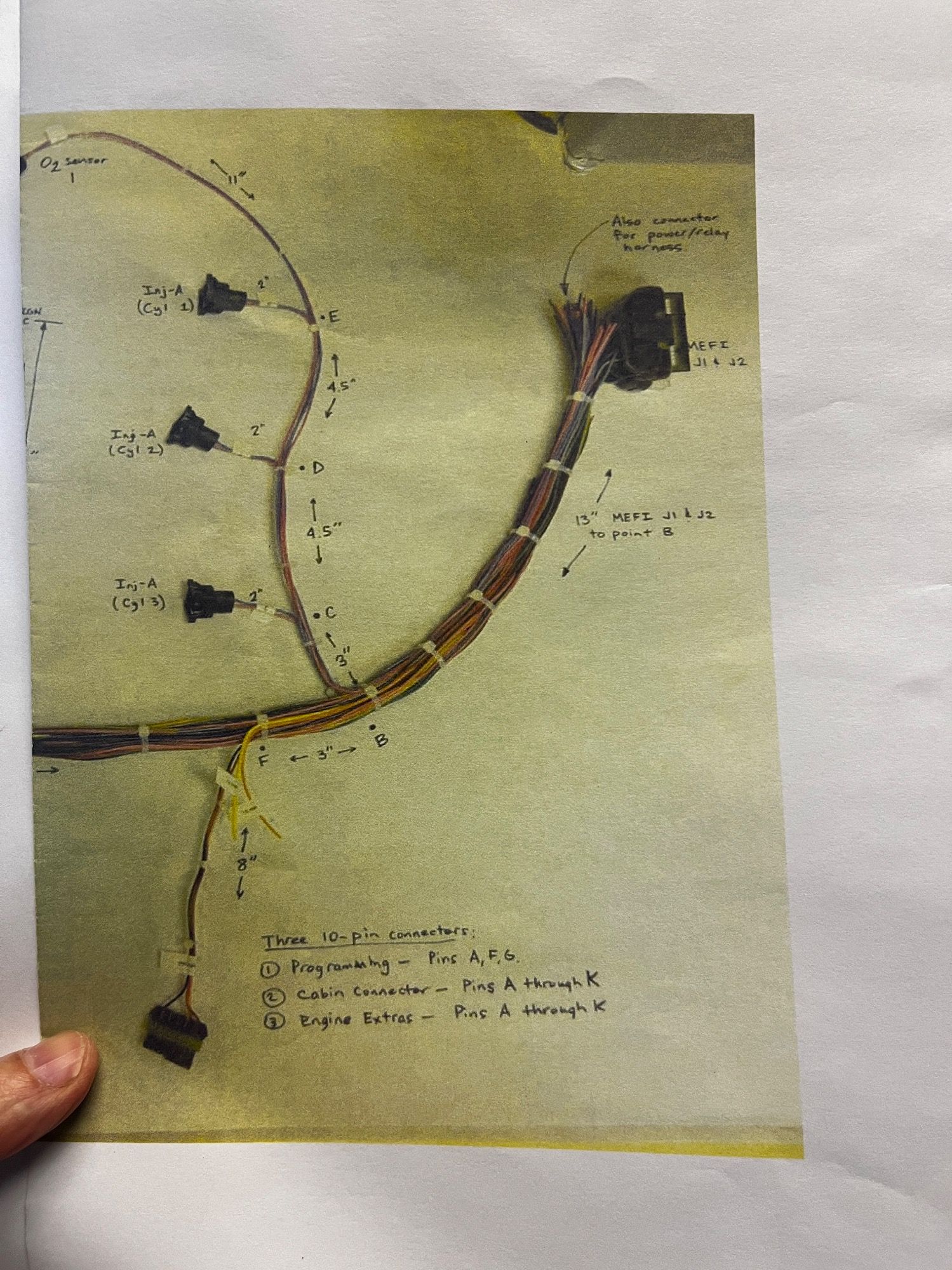

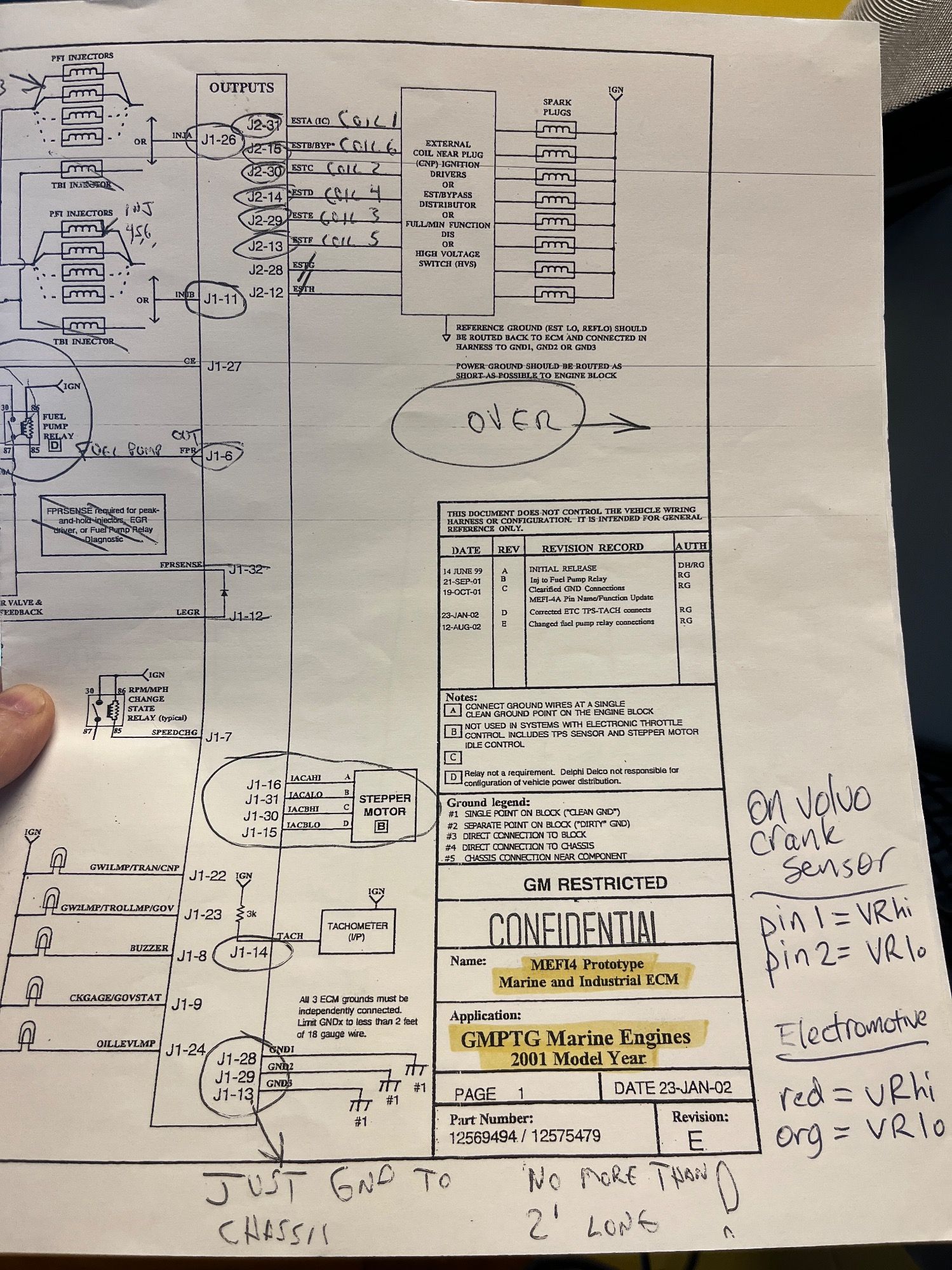

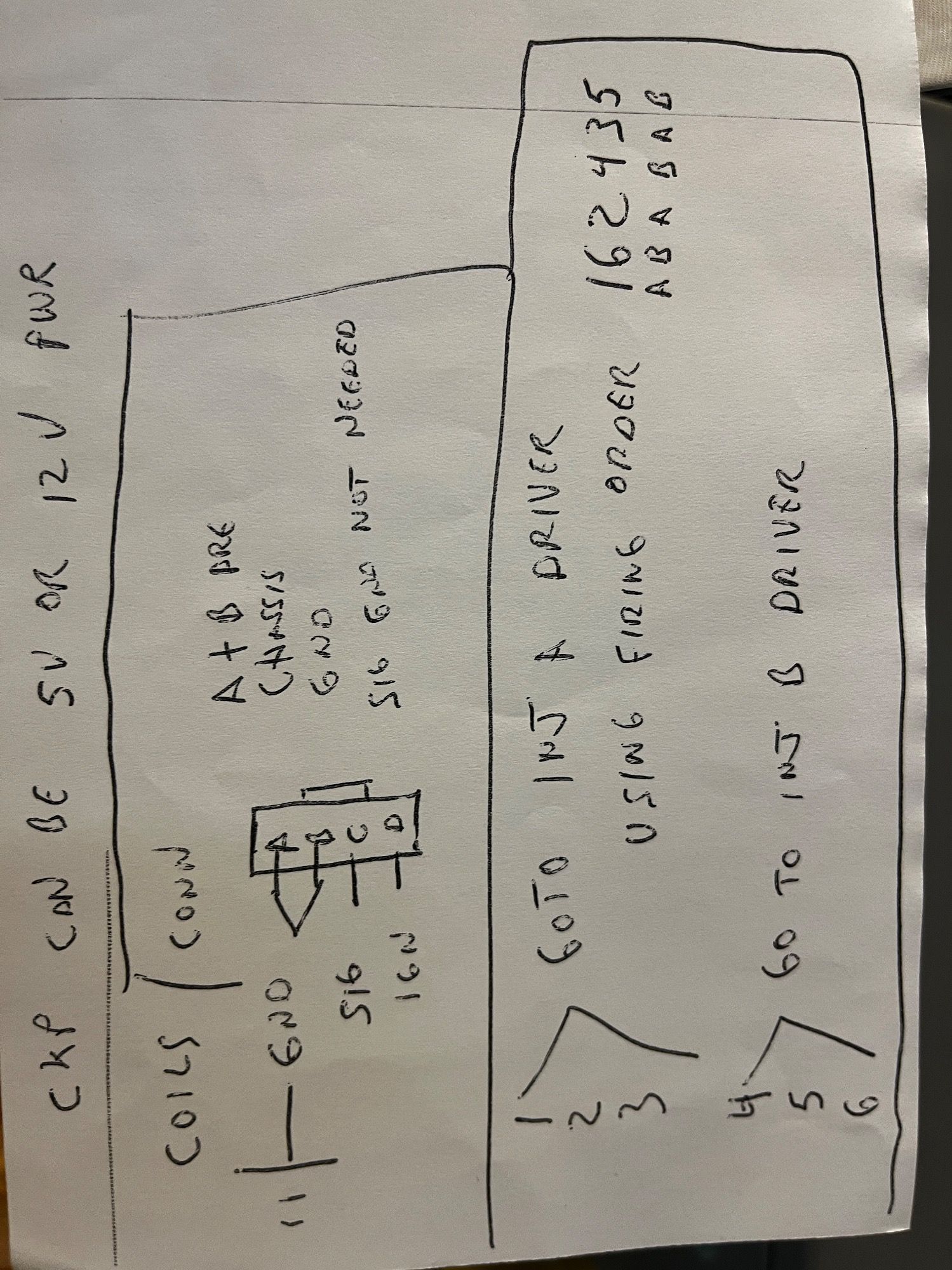

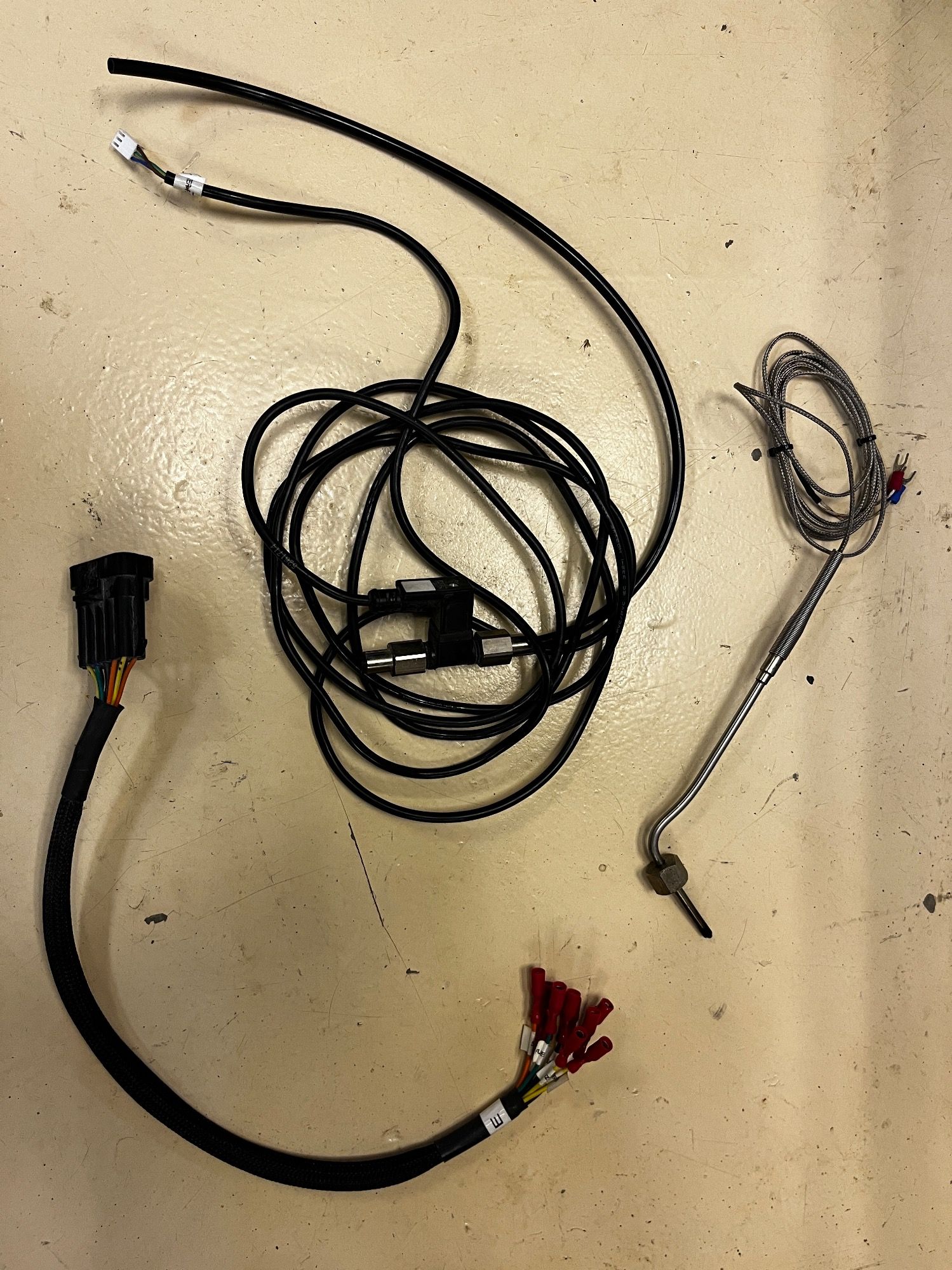

Distributorless (coil-near-plug) twin-plug ignition system, with cables

-

Last run in December 2020 (>> video <<), then removed and stored in air conditioned space

-

Set up for air-to-water intercooler (included) and water/meth injection (see story below)

-

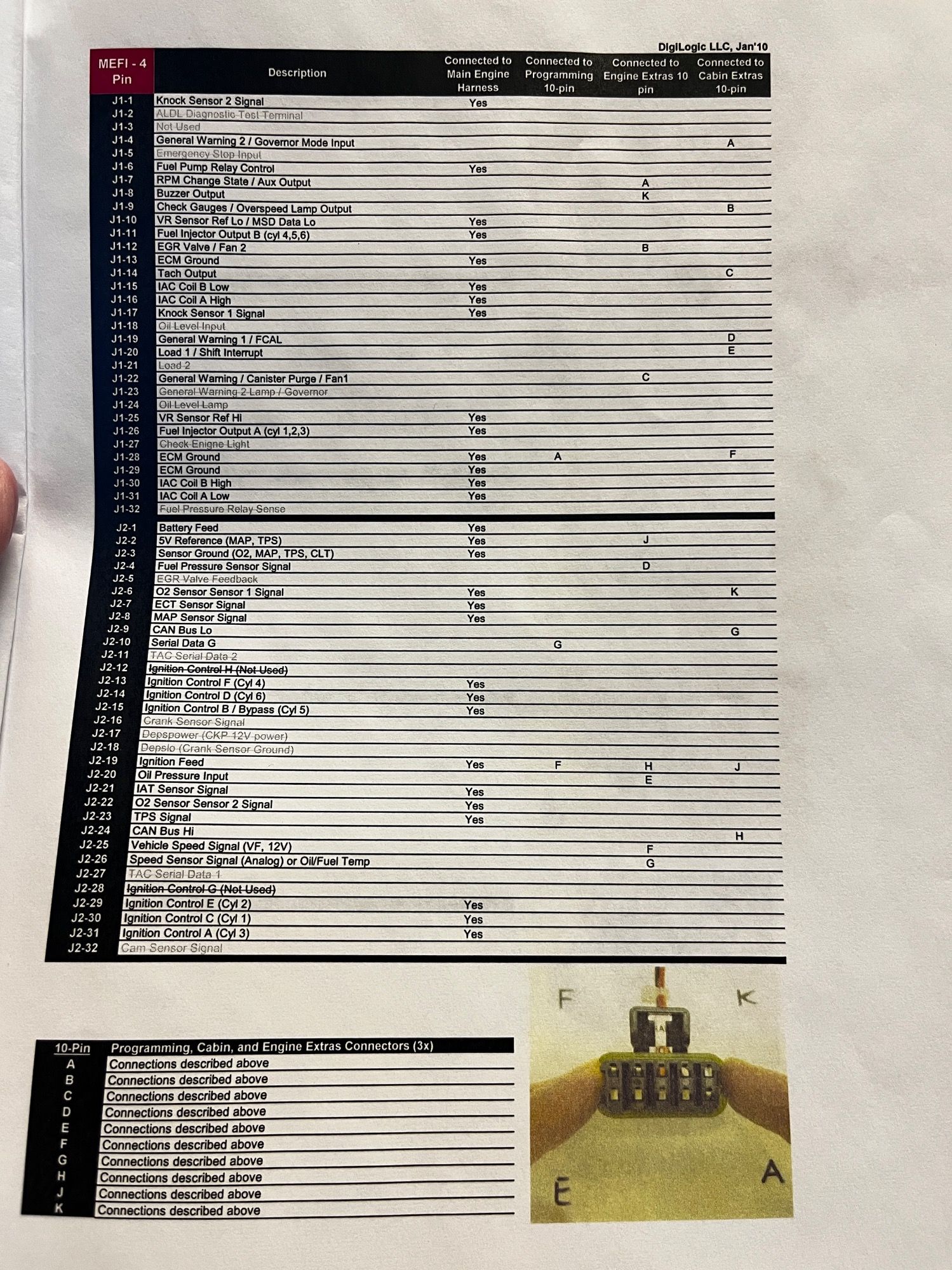

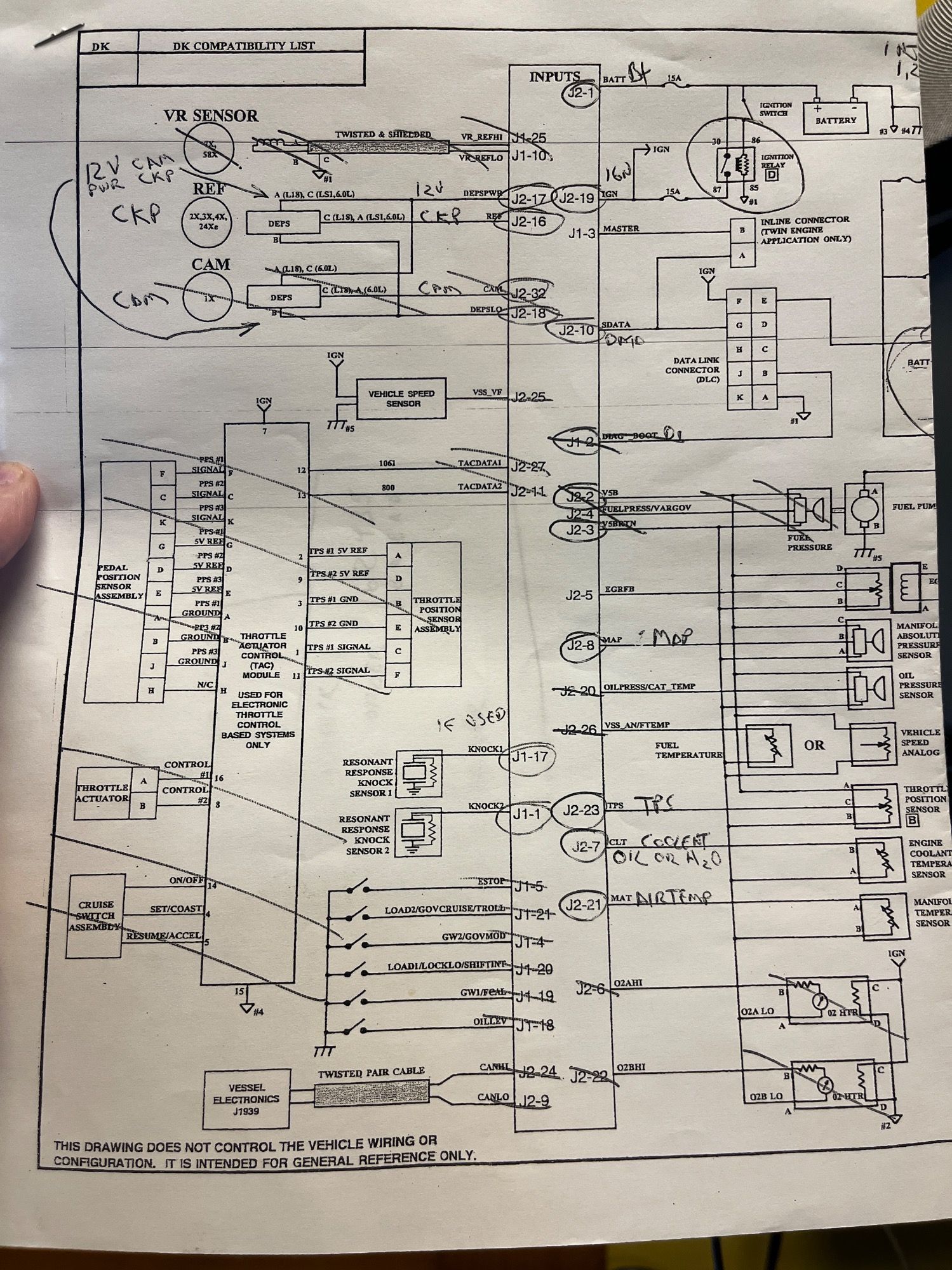

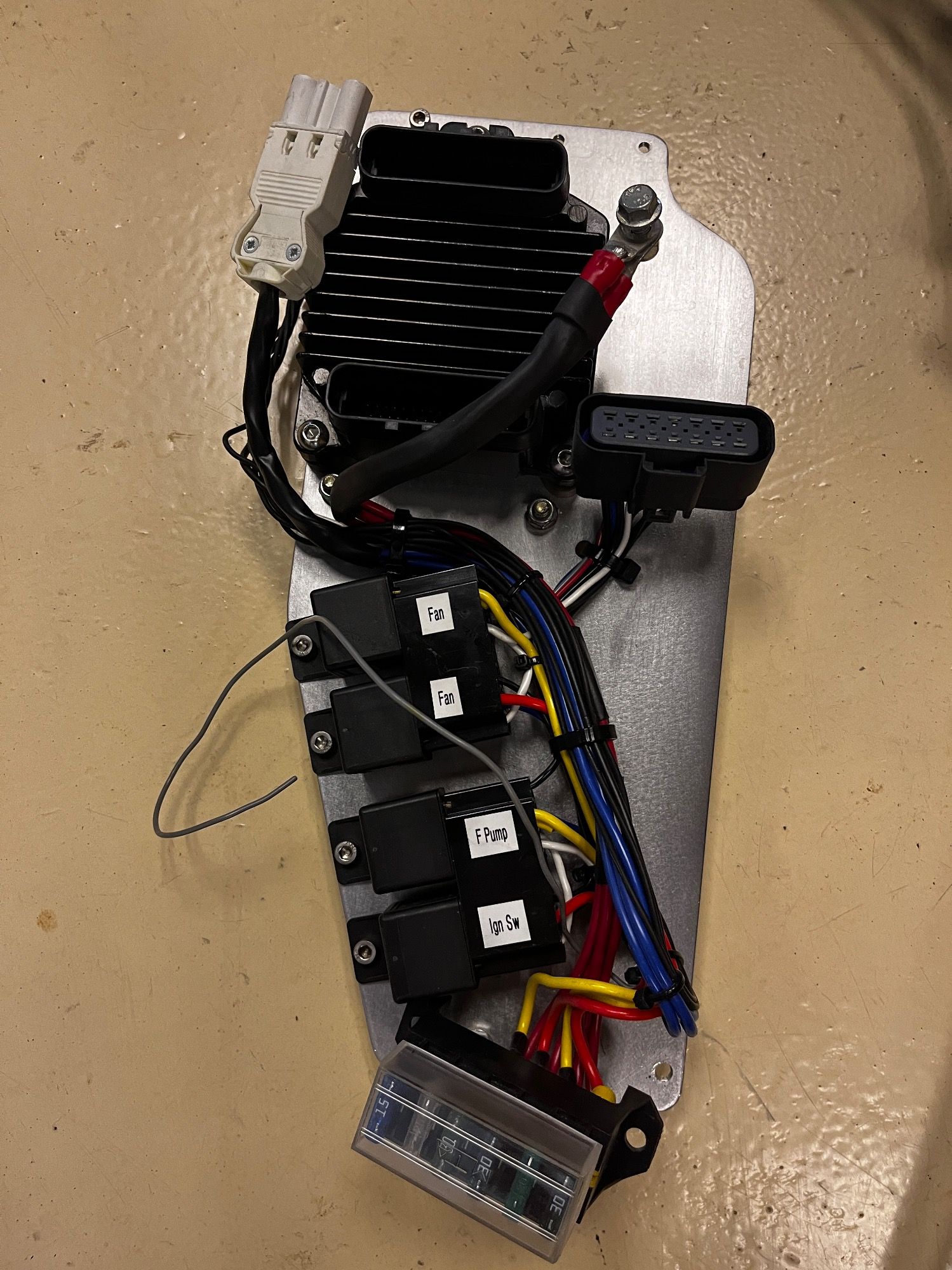

Wired for MEFI-4B ECU, ECU included (see story below)

-

Includes two Innovate LC-1 wideband air-fuel sensors with gauge

-

Includes AEM water/meth flow rate sensor and gauge

-

Includes electric turbo oil scavenge pump

-

Includes CAE shifter

-

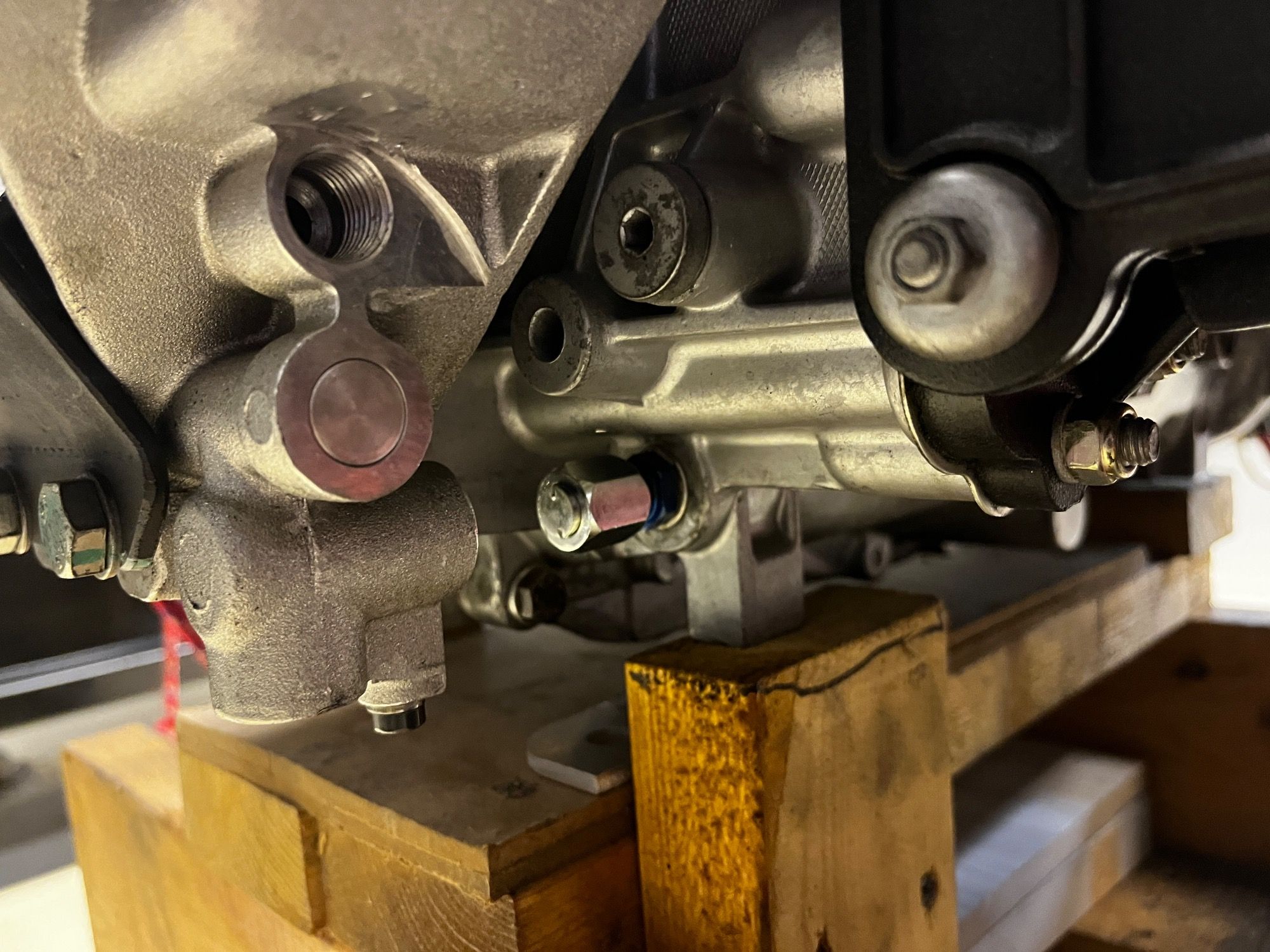

Includes starter motor and clutch slave cylinder

-

Fuel pump

- AEM water/meth injection pump (P/N 30-3015)

- Water pump and radiator for the air-to-water intercooling system

- Halfshafts (CV axles)

- Engine-surround “tin” (sheetmetal)

- A/C compressor or mounting provision for one to be added

How This Story Began

I’ve owned my 911 for 22 years (since October 2001). For the first 5 of those 22 years, it was a daily driver, a largely-stock 964 Carrera 4. In 2006 it was retired from daily use so that it could be a project car and has been driven no more than 1000 miles since that time.

With the help of my friend Todd Knighton from Protomotive, a twin-turbo conversion project was planned and executed. I was an engineering manager with BorgWarner, employed in their turbocharger division, so use of BorgWarner turbos was a must. Todd helped guide me through the engine conversion and ECU control nuances. Aside from his help rebuilding the cylinder heads and preparing them to mate with the OEM pistons and cylinders I had bought from a 993TT car, I have performed all the work on this project. As mentioned earlier, I’ve hardly driven the car at all… I just wanted something I could tinker with.

As you’ll read below, the second phase of the build included a swap to BorgWarner EFR 6258 turbos. I was the creator of the EFR Series turbos so it was serendipitous for the first two EFR turbos ever put on a vehicle were used on my 911 and are included in this sale. The result was an engine with great boost response that delivered 576 hp and 595 ft-lbs to the rear wheels on 1 bar of boost, pump gas, with water/meth injection, with the peak power being limited by the fuel delivery system.

The third phase of the build was where I built a new intake manifold assembly, fuel injection and ignition setup. In hindsight I should have left well enough alone with the prior phase but I wanted larger (60lb/hr) injectors to support more top-end power and wanted to remove the 993TT intercooler I was using so that I could use a flat decklid rather than a turbo-style decklid. I say that I should have left well enough alone because it was during this period that I got very busy with my career and had to neglect the project.

I still own the car but the reason I’m selling the engine is because later in my career I switched professional focus from turbochargers to EV components. I’ve since retired (I led BorgWarner’s Cascadia Motion division www.cascadiamotion.com ) and now that I have sufficient time on my hands, I’m taking action on my plan to convert the car to an EV. I got the turbo itch out of my system years ago and all I’ve focused on for the last 5 years was EV parts and EV conversions. As much as I still appreciate engines, they don’t align with my current preferences.

Initial Engine Build

The car’s engine was 3.6L air cooled from the factory and it was mated to an AWD transmission. My initial build included a rebuild of the engine and replacement of the transmission so that I could remove weight and be 2WD. I retained the stock Carrera 4 rear CV axles which means this transmission has those C4 stub axle/flanges. I can’t recall if those are the same stub axles as what the C2 uses but I can tell you that they are 108mm OD. The CV axles (halfshafts) are not included in this sale, by the way.

There was nothing wrong with the engine, it just needed to be rebuilt to lower the compression ratio. Using pistons and cylinders from a 993TT, the compression ratio was lowered to 8:1. Todd at Protomotive reworked my cylinder heads to match, including new valve guides. I did a light porting job on them, mostly cleanup, since they are so nice from the factory. “Super C2” cams were used from John Dougherty Racing Cams.

As for the air & fuel path, I was using a 993TT manifold center section, intercooler and exhaust manifolds and a pair of turbos from a 996TT (produced by BorgWarner, of course). I used 993TT injectors and the stock distributor, controlled by the factory ECU running a modified chip from Protomotive. None of those parts are included in this sale since they were all replaced later on.

At that point in time I was running low boost (~11psi) on pump gas and making around 500 rwtq and 460 rwhp.

EFR Turbo Conversion and Water/Meth Addition

In 2009/2010 we launched the EFR Series turbochargers and as mentioned above, my car was the recipient of two units from the initial prototype batch. Those two turbos are included in this sale, as they have been on the engine for the last ~13 years and are still perfect. If you want to know more about EFR history and features: https://www.borgwarner.com/docs/default-source/iam/boosting-technologies/efr_technical_training_book.pdf

I CNC milled some stainless adapters to go between the 993TT exhaust manifolds and the EFR 6258 turbos and installed a water/meth injection system from AEM. That system is so cool (pun intended); it monitors flow through a sensor and reports it on a gauge. The controller then modulates the flow of water/meth based on boost. I didn’t actually use straight methanol; I used windshield washer fluid rated for -30F as people using these systems often do since it’s a really low-cost way to add knock resistance. By the time this phase was over, I was making 576hp and 595 ft-lbs to the rear tires on around 1 bar (15psi) of boost, 93 octane gas, and windshield washer fluid. You’ll see this dyno plot in a photo of a printed page in the collection. Unfortunately due to a computer crash, I no longer have electronic records (the raw dyno data). During this phase I realized that I had reached the limit of the fuel system. Even after cranking up the fuel pressure, I was running the injectors wide open (100% duty) which is why power was peaking at 5200 rpm. On the photo of that printed page, you’ll see from the sketched dashed line why I thought ~625 rwhp would be likely with larger injectors.

The 3” stainless exhaust pipes (2) each have a small muffler and they exit the center of the car as shown in one of the photos. Between the muffling effect of the turbos and the small mufflers, the car was not as loud as you’d think it might be.

My buddy Geoff at Full-Race made me some stainless exhaust manifolds to replace my 993TT + adapter setup. They look great from below the car.

Anyone who has done turbo conversions on Porsche air cooled engines knows that oil control can be a problem. This system uses pressure feed from the engine, “anti-drip” valves on the turbo oil inlets, an electric scavenge pump (which is included) and a check valve installed in the hose between engine and oil tank. All this combined with running the oil tank level at about ½ full yielded a smoke-free experience.

Custom Intake Manifold and Control System

The only legitimate reason for this next phase was to install larger injectors. What can I say, I slipped down that slippery slope and decided that I also wanted to be able to use a flat decklid (for aesthetic reasons) and I was growing fond of carbon composites and standalone ECU’s.

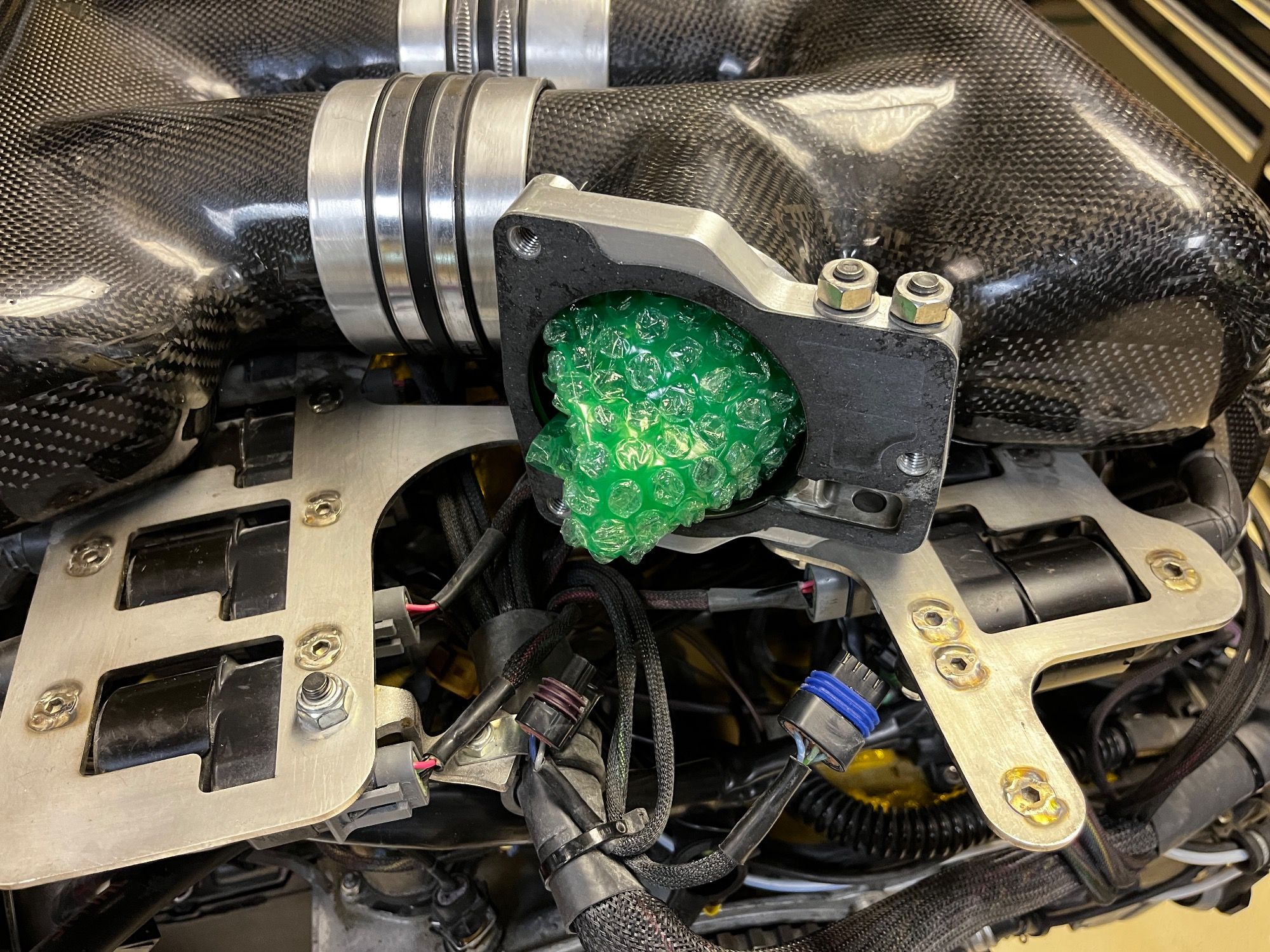

So I had this crazy plan to CNC mill a mold for a custom intake manifold and then build the carbon parts from that mold, terminating the ends with custom-machined CNC aluminum bits. It was a huge project; a fun learning experience but very time-consuming. This intake manifold would also serve as the holding bracket for 12 coil packs (LS1-type) to deliver coil-near-plug ignition and allow removal of the factory distributor and used a custom wiring harness for a MEFI-4B ECU. In hindsight I should not have used this ECU and I would suggest the future owner of this engine replace it. The user interface for the MEFI is clunky and with poor diagnosis and datalogging capability. So why did I use it? I wanted something small and tidy and as it turns out these were not good enough reasons. Included with the sale is the laptop cable and USB key. Again, the buyer is advised to move on to a modern ECU. I cannot support MEFI-related questions post sale; all I can confirm is the engine will start and run on the included ECU if you wish to use it or at least begin with it. Wiring schematics are included in the sale in case you want to re-use the sensors and wiring but with a different ECU.

By the time all the fabrication was complete, I had run out of time and was faced with a cross-country job assignment that ultimately led to my loss of interest in ICE propulsion. However, I spent enough time to get the engine running on the new control system so that I could at least start, idle, and drive the car gently. I did only low-rpm non-intercooled tuning and the system never saw more than 3000rpm. I moved away for 6 years and the only thing I did in that period was remove the engine in December 2020 and made a short video clip to document the condition before removal: https://youtu.be/KXTIcnans38

To be able to run a flat decklid, I re-fabricated the charge air pipes and reconfigured it for a water-to-air intercooler. This intercooler was plumbed to the same tank as the water/meth injection system which means all the charge air and combustion cooling would run from a single fluid (windshield washer fluid) which I would then refill as needed.

The “MechTronics” logo on the intake manifold is a throwback to a small company my wife and I operated as a side-hustle in the late 90’s. It’s buried in the clear coat; it’s not a decal you can remove and I’m sorry for that. The manifold has a valve between the two plenums that I had intended to use as a variable plenum size feature but just wired it open, at least to start with.

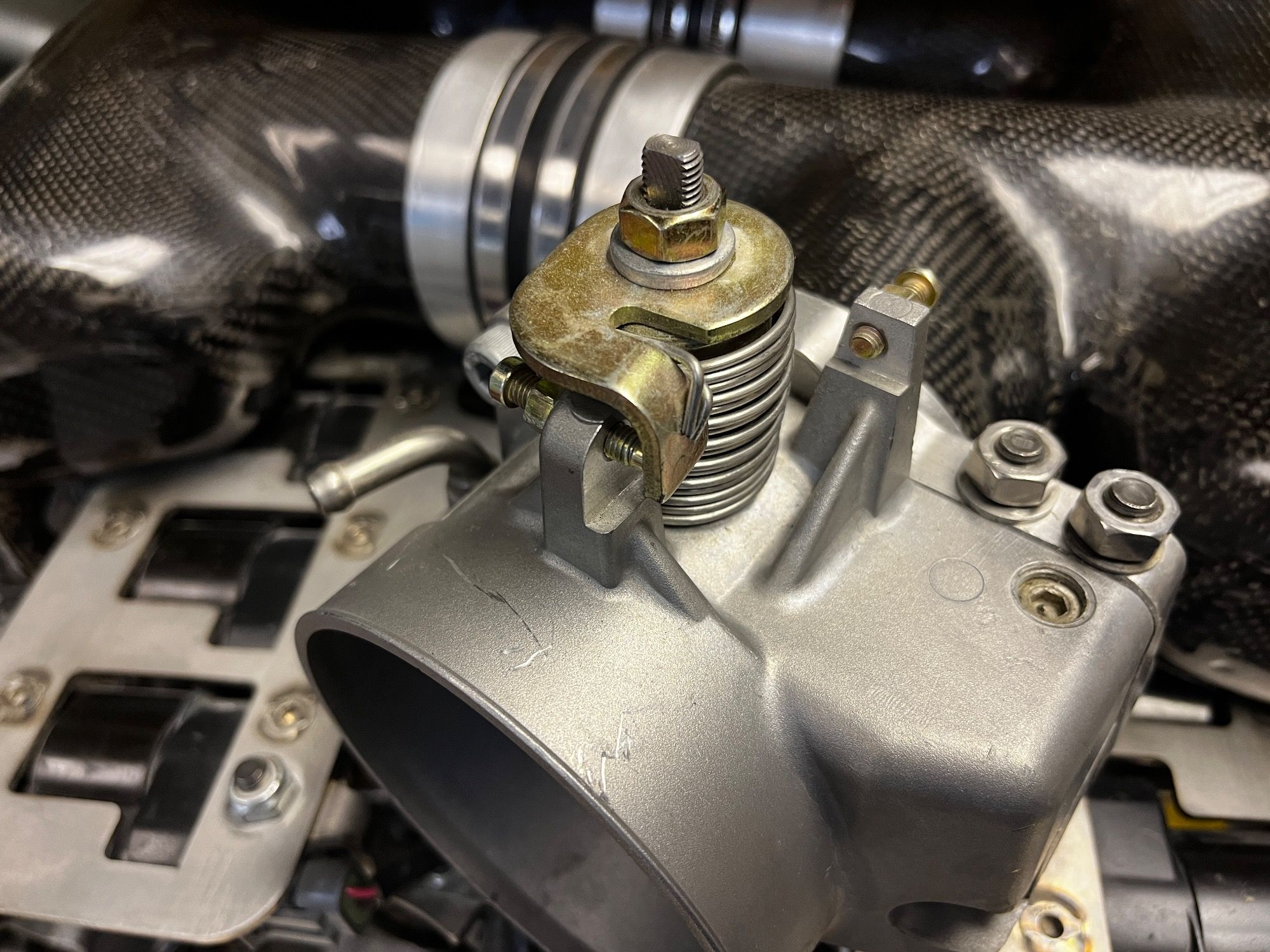

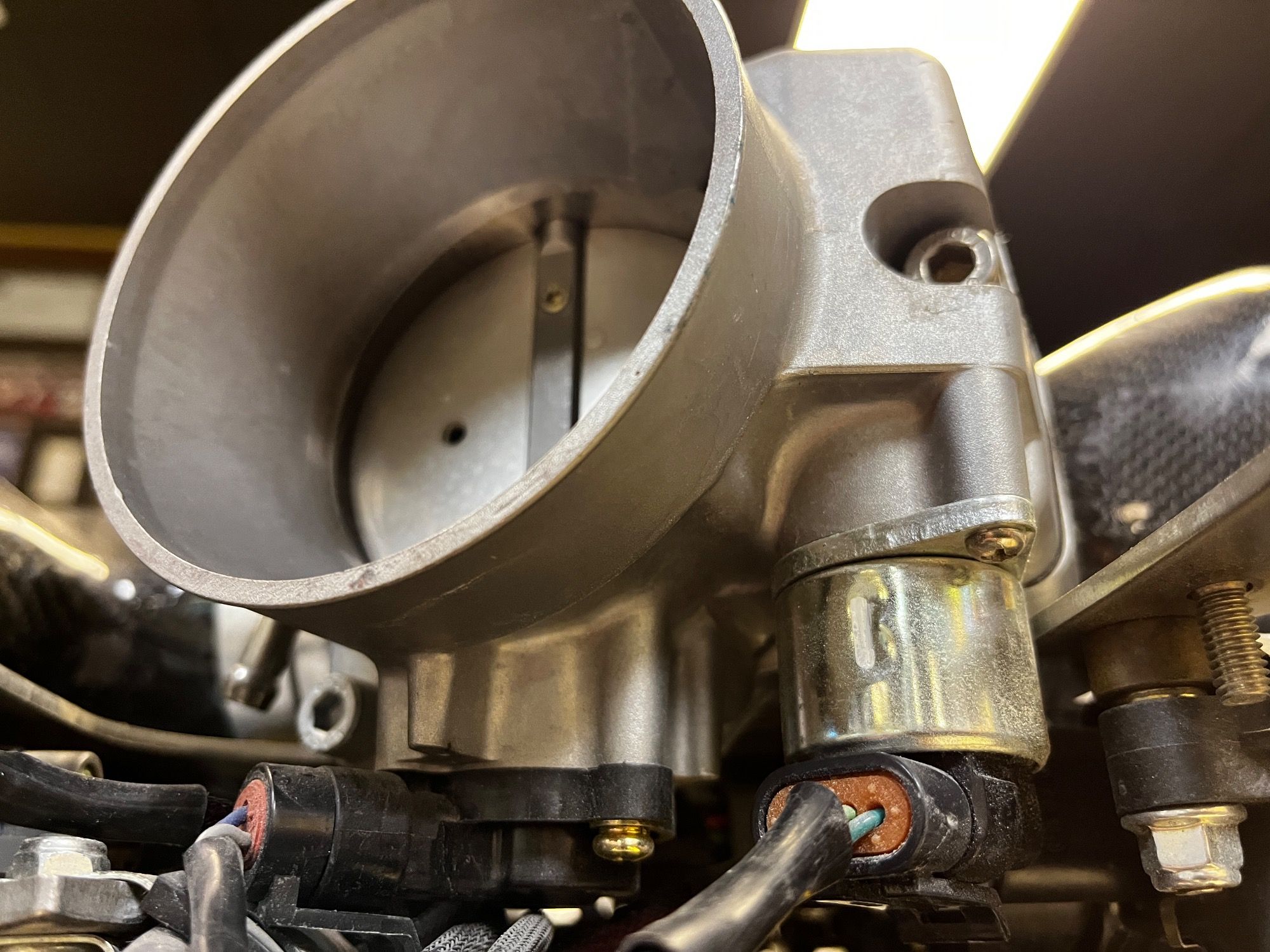

The throttle body is a large one from some kind of V8, perhaps a LS engine. It’s equipped with a quarter-turn crank that you’ll need to attach your throttle cable to. This aspect is not plug-and-play. The throttle body is of course equipped with an IAC motor and TPS.

This Engine Has Sold

But Here's What Was Bought

These days, even HIGH MILEAGE 964/993 engines go for $25k+. This package offers so much more given that I’m including the EFR turbos and all associated plumbing, the water/air and water/meth equipment (minus the pumps), the control system, the G50 transmission with Quaife limited slip diff and torque-capable clutch and the awesome CAE shifter (which sells for $1700 alone). It’s a rare chance to own a very powerful powerplant, with a compelling history, to drop into your special air-cooled Porsche. Given that you don’t need to use a turbo tail, it’s a chance to make a very fast sleeper.

The history is disclosed as completely as possible but given that the story spans over the course of 17 years, it’s very likely that I have forgotten many details. Questions are welcomed both during and after the sale (via email only) and I’ll do my best to conjure up the answers. Given that most of the work took place before smartphones were available, I don’t have photos to reference other than those shown below.

The engine package is being sold “as-is” and without warranty. The video taken in December 2020 shows the engine idling and running at the time it was removed from the car in preparation for the upcoming EV conversion.

Since I had to abandon the project some years ago due to career-related obstacles, I had only tuned up to 3250rpm, at which it made 220 whp. This was with the water/air intercooling system un-filled and water injection system turned off. Keep in mind the stock 964 power level is ~230 whp (but at a much higher RPM of course!). So, it started well and drove well, delivering OEM-like peak power. Meaning, even with that tune of very limited rev range, the car was completely usable. With all that being said, the new owner is advised to replace the ECU and pay someone to do full-map tuning if they are not well-versed in doing it themselves. But you've got a system included that will run right out of the box after adding a suitable fuel pump, and allow you to drive the car around, limited to 3250 rpm.

As a reminder, this engine has neither A/C (compressor) nor cabin heat (exhaust manifold heat boxes) provisions.

I had all this sold on “verbal commitment” but unfortunately the buyer had to back out due to medical reasons which is why it is already packed and crated. The good news is that it’s now ready to go to the next buyer. The bad news is that I can’t take any more photos since everything is wrapped and crated.

The crate is 36 x 36 x 41” (including the pallet it’s attached to) and weighs approximately 850 lb. I will ship it to your location, at your cost, via truck freight. For reference, it was going to be $950 for me to ship it from western NC to southern CA, including being insured at full value.

Thanks for reading. If you're an interested buyer, please send me an email!